Cold Storage (-38°C) Fire System Optimization Case Study

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Project Name

Cold storage (-38 ℃) project

Project scale

17307.34m ²

Application scenarios

Food research and development, production, and processing

System

Fire water supply system

Sprinkler system

Pump room system

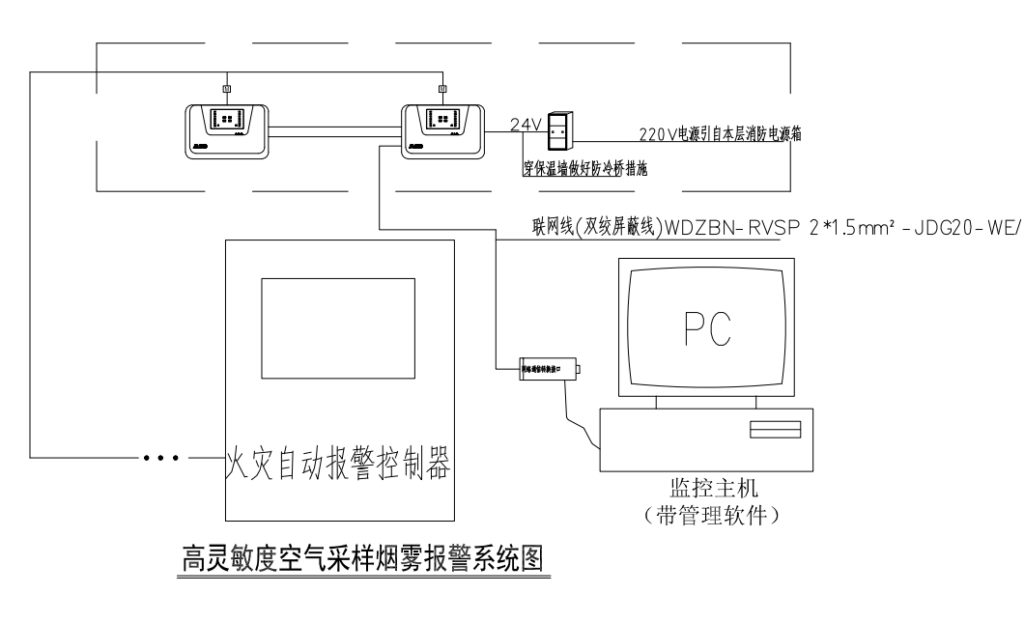

Automatic alarm system

The Challenge

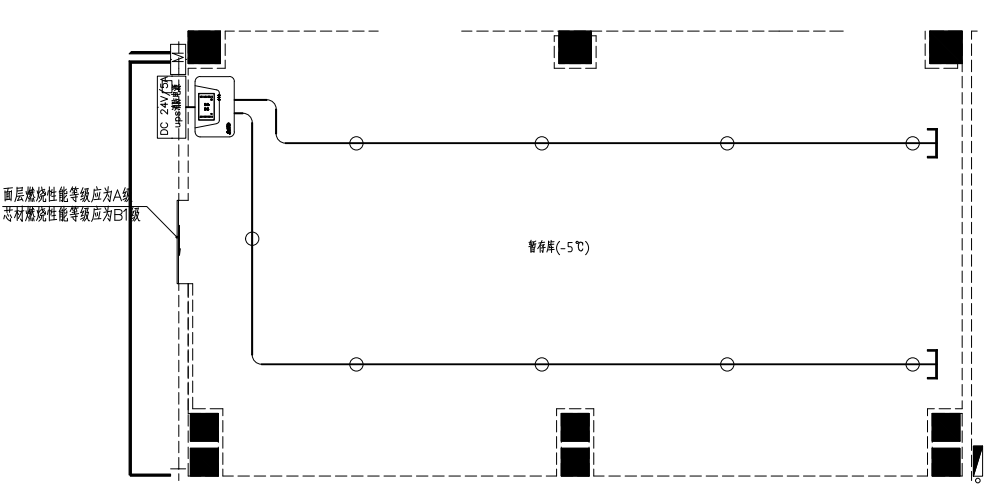

As a leading food research and development, production, and processing enterprise, the customer’s factory has a special process environment of -38 ℃ freezer/refrigerator on the 1st and 2nd floors.

The extreme low temperature and high moisture environment make traditional fire-fighting equipment (such as smoke detectors and sprinkler systems) unable to guarantee normal operation in low temperature environments

Our Solution

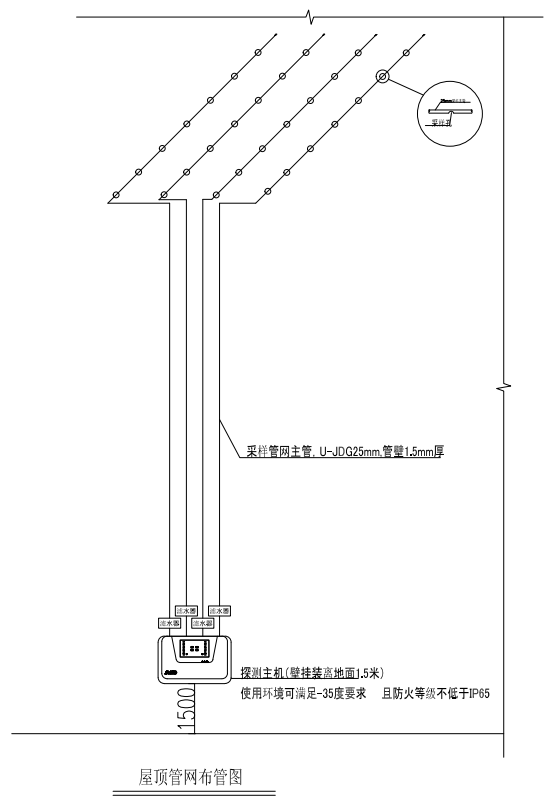

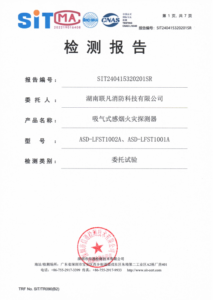

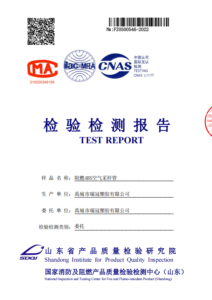

The Omnifir team designed and implemented an Aspirating Smoke Detection System (ASD) based on mature optical and electronic technologies, tailored to the unique nature of the project.

1)Equipment Performance Based Design

Core technology: Adopting a suction type smoke fire detector, which is linked with the host to analyze particles in the air in real time.

High precision: This device can accurately distinguish between fire smoke particles and interference particles such as dust and water vapor with similar diameters.

Low temperature

adaptability: Relying on its excellent low temperature adaptability, the system ensures stable operation in extreme environments of -38 ℃.

Early warning: The ability to detect fires without seeing smoke, enabling timely warning in the early stages of a fire and achieving early intervention in fire supervision.

Optimization content: Optimize the original alarm and sprinkler fire extinguishing devices into an air suction alarm system.

2)Standardized Construction and Quality Assurance

Construction technology: Adopting the special technology of “no opening, no filling”.

Effect: Completely prevent cold air leakage in the later stage of the cold storage, ensuring refrigeration efficiency and structural integrity.

Benefit: Significantly reduced the installation complexity of alarm and sprinkler equipment, reduced installation costs by about 30%, and significantly reduced potential maintenance workload and failure risks in the future.

System advantages: Improved overall system stability and product lifespan, achieving a comprehensive leap from “compliance” to “optimal configuration”.

Core Value

On the premise of fully meeting fire prevention and fire safety regulations, the new system is designed to:

High Agility

High Reliability

Low Maintenance Cost

Global Delivery Guarantee

We deliver from Blueprint to Jobsite.

- Source Quality:Control:Rigorous selection of international standard (CE/UL compatible) materials to withstand long-haul logistics and harsh African climates.

- Export Packaging:Professional reinforcement and shock-proof packaging. Mandatory fumigation for all wooden components to ensure smooth customs clearance.

- Lifetime Support:From logistics tracking to 7x24h technical response by the original project engineers. We ensure zero delays in resolving site issues.