Case Study: Stainless Steel Customized Fire Protection Products Project

Project Overview

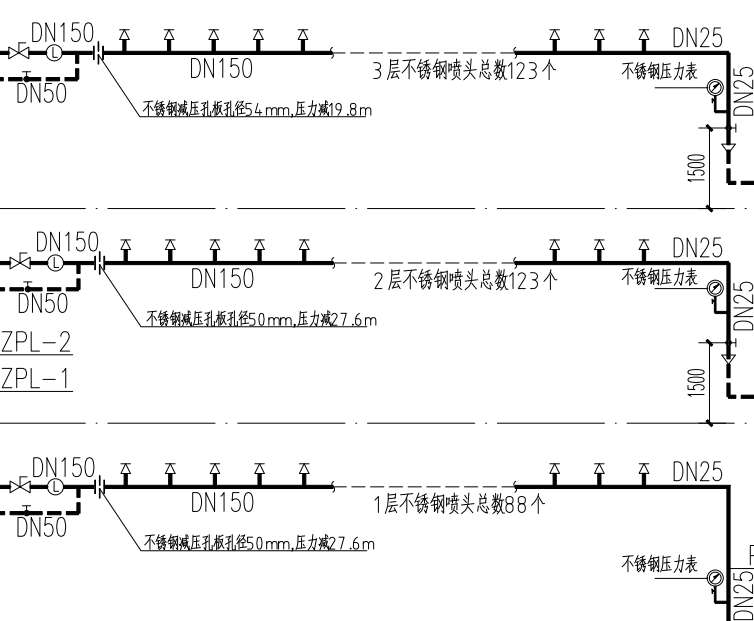

Project Scale: The total construction area of the project is 82,051.96 m2, including 10 floors above ground and 1 floor underground.

Architectural Parameters: The building height is 31.8m, utilizing a frame structure with a Grade II fire resistance rating.

Systems Covered: Includes key facilities such as fire water supply systems, sprinkler systems, pump room systems, automatic alarm systems, and smoke control/extraction systems.

Process Background: Production and processing of new energy materials.

The Challenge

Core Background: The client is a leading domestic enterprise in high-purity elements and specialized electronic materials manufacturing, recognized as a High-tech and “Specialized, Finesse, Peculiar, and Innovative” enterprise.

Special Environmental Requirements: The production workshops (Workshops 1#, 2#, 3# and the testing workshop) have extremely strict control requirements for the content of metal elements such as copper, iron, zinc, and nickel.

Drawbacks of Conventional Equipment: Standard fire protection equipment struggles to adapt to high-purity environments; long-term operation leads to corrosion and damage, which compromises reliability and poses potential contamination risks to the production environment.

Our Solution

The Omnifir team conducted an in-depth analysis of the project’s characteristics and designed a complete set of stainless steel fire protection equipment solutions, enhancing durability while maintaining full fire suppression performance.

A. Performance-based Design of Stainless Steel Materials

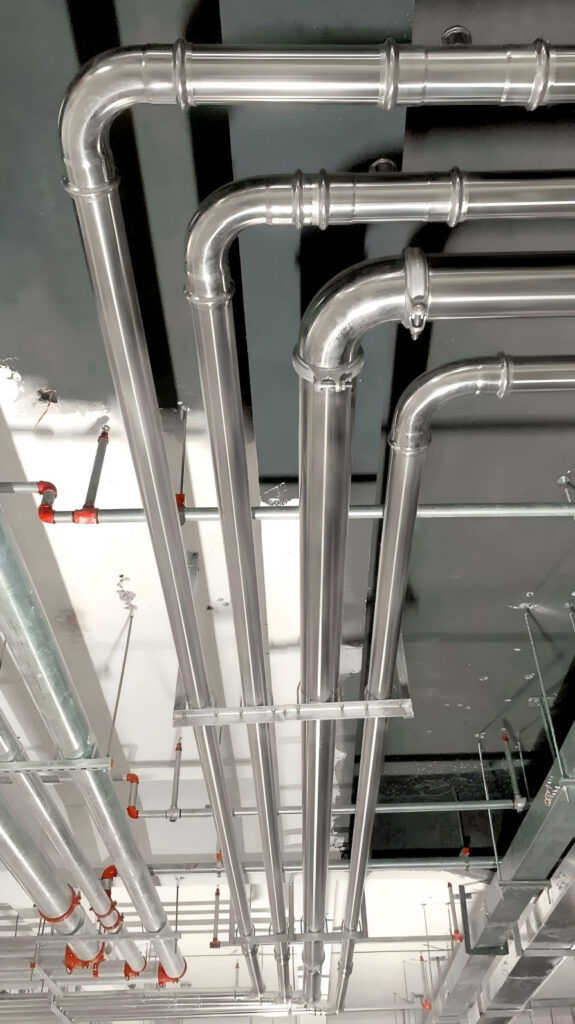

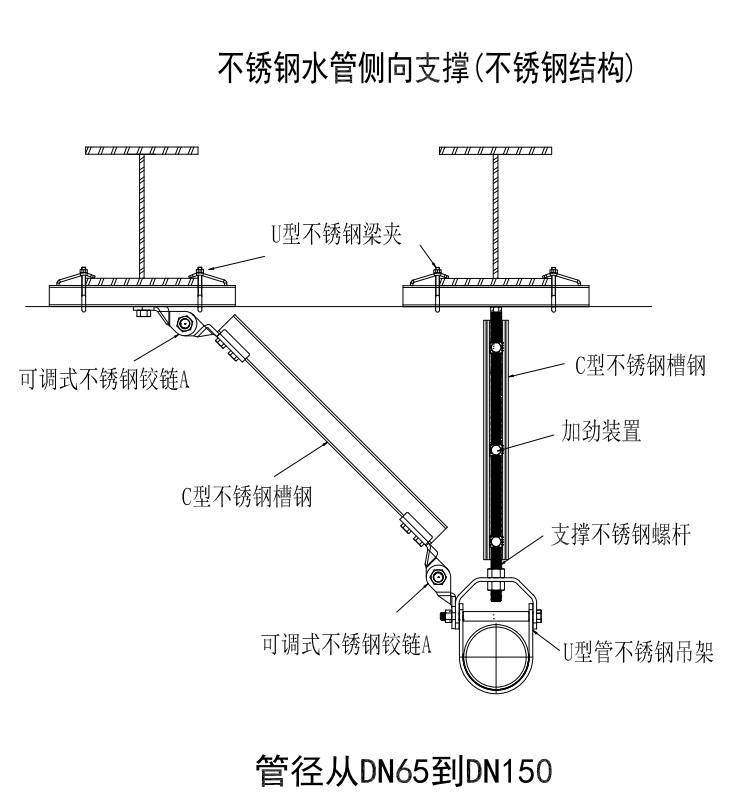

Key Upgrades: Core components such as sprinkler devices and piping systems were fully upgraded to stainless steel.

Performance Advantages: Leveraging excellent corrosion resistance and low-temperature adaptability to ensure stable equipment operation in various extreme environments.

B. Standardized Construction & Quality Assurance

Environmental Protection: The renovation significantly reduced the risk of metal ion contamination in the workshop caused by equipment corrosion.

Long-term Benefits: Extended the service life of equipment in complex environments, overcoming the shortcomings of conventional equipment prone to rust and failure.

Production Assurance: Provides a solid guarantee for continuous safe production and low-maintenance operation of the workshop from a long-term perspective.

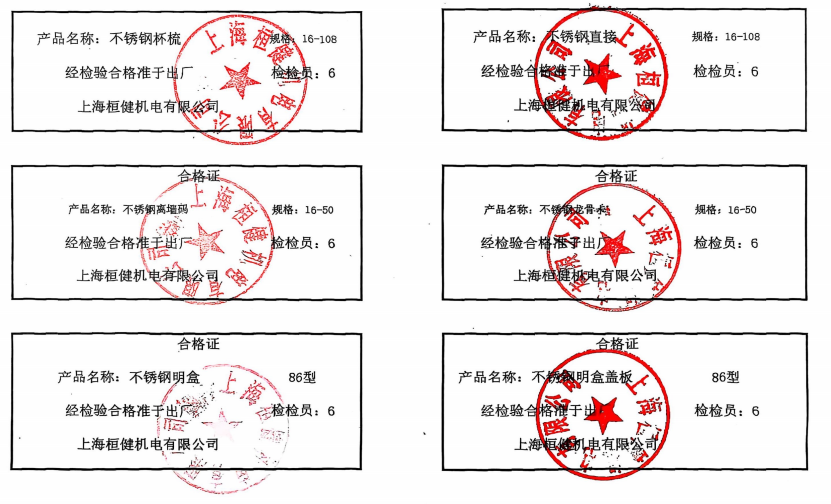

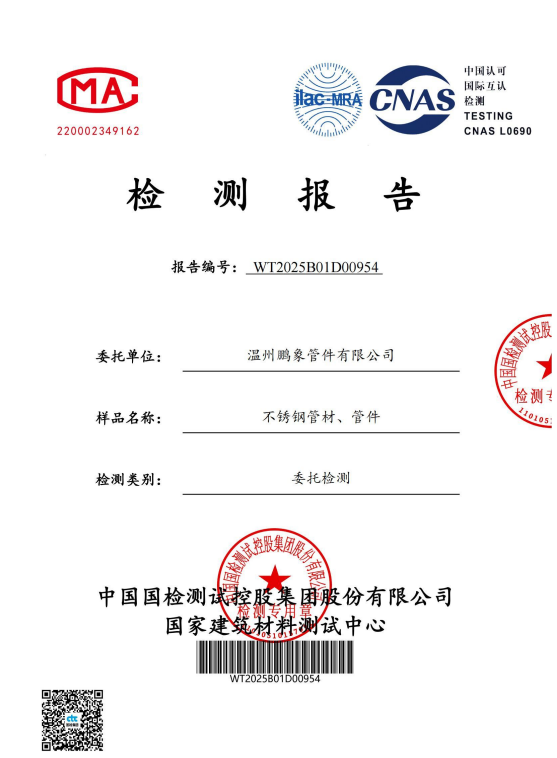

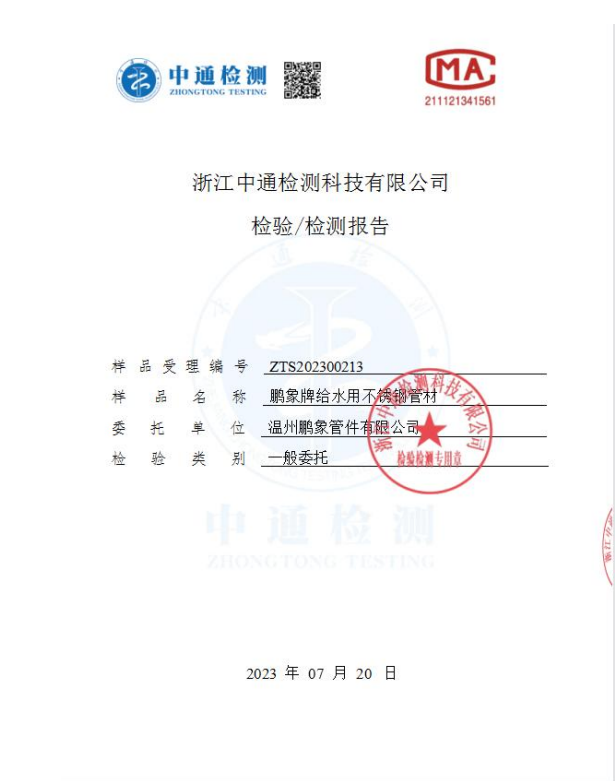

Certification

Qualification: The project includes a full set of product certificates, ensuring all customized stainless steel equipment complies with industry safety standards.

Global Delivery Guarantee

We deliver from Blueprint to Jobsite.

- Source Quality:Control:Rigorous selection of international standard (CE/UL compatible) materials to withstand long-haul logistics and harsh African climates.

- Export Packaging:Professional reinforcement and shock-proof packaging. Mandatory fumigation for all wooden components to ensure smooth customs clearance.

- Lifetime Support:From logistics tracking to 7x24h technical response by the original project engineers. We ensure zero delays in resolving site issues.