Construction of fire hydrant system

Spray system construction

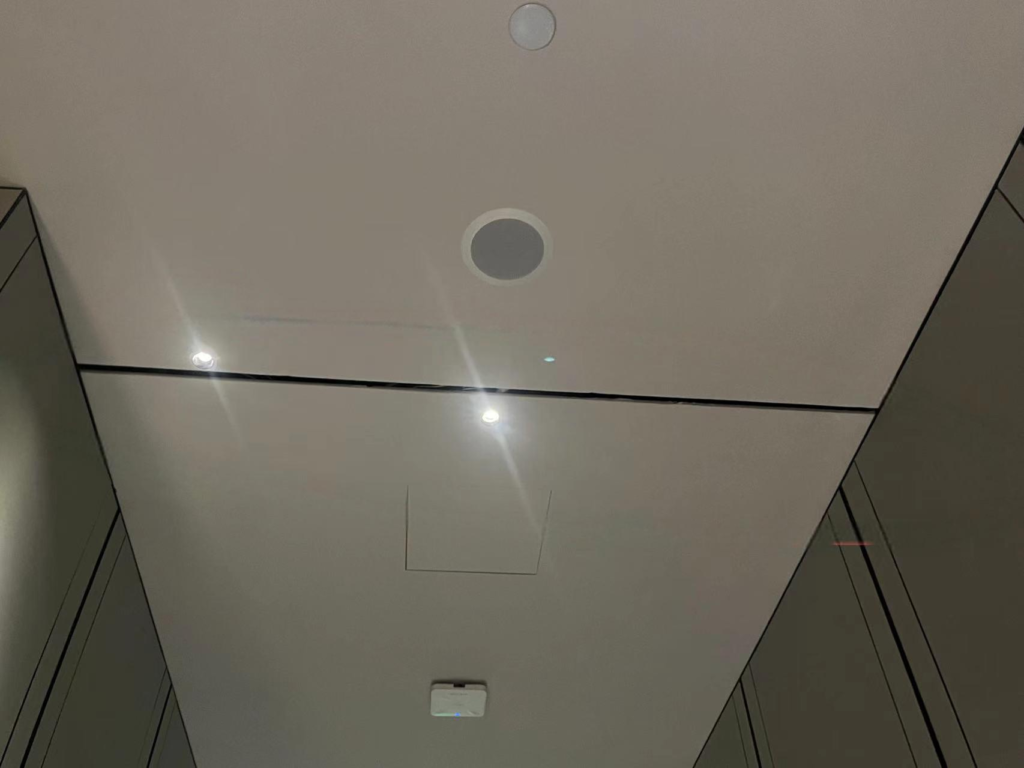

Construction of automatic alarm system

Construction of emergency lighting system

Construction of smoke control and exhaust system

Construction of pump room system

Integrated Fire Protection Systems for Super High-Rise Office Buildings

Project Overview

Project Scale: Total construction area of 65,739.90 m2, with a height of 183.6m (43 floors above ground, 3 floors underground).

Structure: Frame structure with Grade II fire resistance rating.

Core Systems: Fire water supply, automatic sprinkler, pump room, fire alarm, and smoke control systems.

Challenges and Solutions

Challenge 1: Complexity of Pipeline Layout in Super High-Rise Structures

Challenge: With a building height of 183.6m and 43 floors of high-end office space, the internal electromechanical pipelines are extremely dense, making design conflicts highly likely.

Solution: Omnifir implemented full-cycle BIM technology, conducting multi-disciplinary 3D modeling and deep collision detection before construction. This pre-identified and resolved spatial conflicts, effectively eliminating the risk of on-site modifications.

Challenge 2: Difficulty in Interdisciplinary Collaboration and Management

Challenge: The project encompasses multiple complex systems including fire water supply, sprinklers, alarms, and smoke control, requiring exceptional organizational skills to ensure seamless coordination between trades.

Solution: We established a matrix-based organizational structure, with a specialized management department composed of experts with over 10 years of experience. A vertical leadership system was implemented for each sub-system to ensure clear instructions and rapid response.

Challenge 3: Stringent Construction Schedules and Resource Allocation

Challenge: In a massive project of over 65,000 square meters , resource supply and task sequencing must achieve “zero waste” to ensure on-time completion.

Solution: Relying on an information-based collaboration platform, we conducted precise material analysis and procurement planning based on BIM models. Progress information was dynamically integrated to scientifically coordinate the interlaced operation of different work stages.

Challenge 4: High Standards for Pump Rooms and Core Systems

Challenge: Super high-rise buildings demand extremely high safety standards for the stability and response speed of pump room systems and automatic fire alarm systems.

Solution: Through refined work plans and the application of forward-looking technologies , we systematically deployed the pump room and six major fire protection systems, ensuring the entire project remained controlled and met Grade II fire resistance standards.

System Category / Construction Content

A. Hydrant System

Installation and pressure testing.

B.Sprinkler System

Deployment of automatic sprinkler systems.

C.Fire Alarm System

Intelligent detection and linkage control.

D.Emergency Lighting

Evacuation signage and emergency lighting.

E.Smoke Control

Ventilation, smoke exhaust rooms, and ductwork.

F.Pump Room System

Fire water source and core pump set commissioning.

Global Delivery Guarantee

We deliver from Blueprint to Jobsite.

- Source Quality:Control:Rigorous selection of international standard (CE/UL compatible) materials to withstand long-haul logistics and harsh African climates.

- Export Packaging:Professional reinforcement and shock-proof packaging. Mandatory fumigation for all wooden components to ensure smooth customs clearance.

- Lifetime Support:From logistics tracking to 7x24h technical response by the original project engineers. We ensure zero delays in resolving site issues.